High-density Storage through Rack Design & Slot Sizes

Project Type: Research

LoDI Team: Kevin Gue

Overview

When we store physical items in a space like a warehouse, we might end up with a very high-density storage system. Which means it is more difficult to have access to the desired item. In most cases, we need to move interfering items to reach that particular item. To handle this problem a simple but effective algorithm is designed to occupy the storage space densely with a limited number of interfering items.

Purpose and Need

By developing a business, it seems obvious that the need for more spaces also increases. In populated areas, it is more crucial to use the available spaces efficiently. Increasing the number of levels, using underground spaces, and decreasing the aisle space are common ways for businesses to develop space utilization. It is the main challenge of warehouse and distribution center managers, on one hand, to increase their available space density as much as possible and on the other hand keep every item accessibility cost in a reasonable range.

The following two reasons are the main factors helping high-density storage to develop:

1. High cost of real estate near population centers where firms would like to locate to reduce transportation costs.

2. The increasing cost of labor relative to the technology-based system should make an automated labor-free storage system more attractive.

Methodology

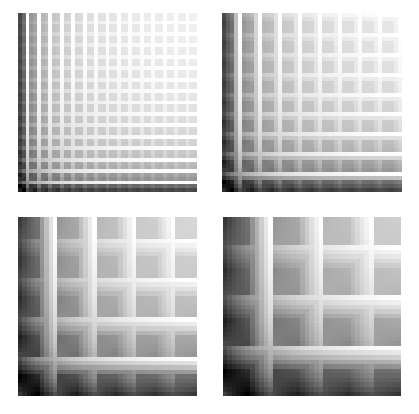

First, it is important that to find out in a m×n space what is the maximum number of items to be kept in a K-deep layout. In a K-deep layout to access every item at most, we need to move K interfering item. We introduce our algorithm Fill-And-Rotate. This a simple algorithm based on a simple labeling procedure and a series of grid rotation. Figure 1 represents m×n storage space occupancy using this algorithm. Also, optimality or non-optimality of this algorithm has not been proved, it has two certain outcomes. First, the upper bound for any K-deep storage layout is less than or equal to (2k) ⁄ (2k+1) and, second, the density of a k-deep layout produces by this algorithm is within 1 ⁄ n + 1 ⁄ r of optimal where r = min {m, n}.

Results and Impacts

1. The best layouts for VHD storage spaces have a definite structure: items should be arranged in several aisles connected by a single cross-aisle.

2. When possible, rectangular storage spaces should be designed such that the length and width are equal to or slightly less than multiples of 2k+1.

3. Long, narrow storage spaces with the narrow dimension equal to a small multiple of 2k+1 are particularly dense.

4. The storage density in a space can be no greater than, and this bound is asymptotically tight as the storage space gets large. Engineers might use this as a rule of thumb when designing storage spaces that will be faced with the need for high density.

5. The ubiquitous single-deep pallet rack can provide no greater storage density than 2/3, and double-deep pallet rack no greater than 4/5.

- Kevin R. Gue, Very High Density Storage Systems, IIE Transactions 38 (1), 93-104, 2006.